TYPES OF BEAMS

Beams are horizontal members that transfer loads imposed vertically. Load transferred on the beam is external along the axis i.e. its length to its support such as columns, foundations, walls, etc. Beams carry transverse load that runs horizontally and the sloping beams transfer both axial and transverse load and deflect by bending.

Beams are categorized based on the types of support, loading conditions, cross-section, materials that are used, etc.

1. Based on Support Conditions:

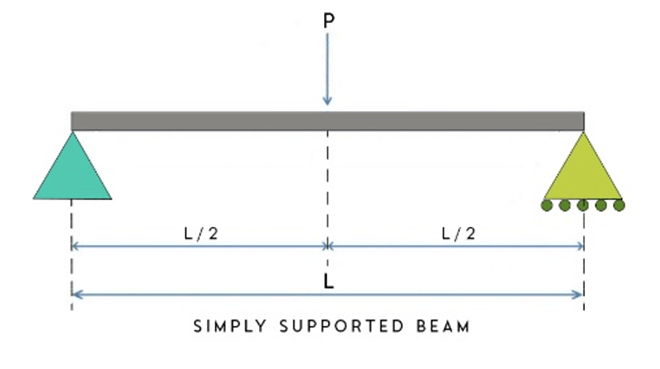

- Simply Supported Beam: Simply supported beams are the basic but important type of beam that is supported at the ends. These beams are unconfined to rotate as one end is roller support and the other is pinned support. Simply support beams experience shearing and bending force.

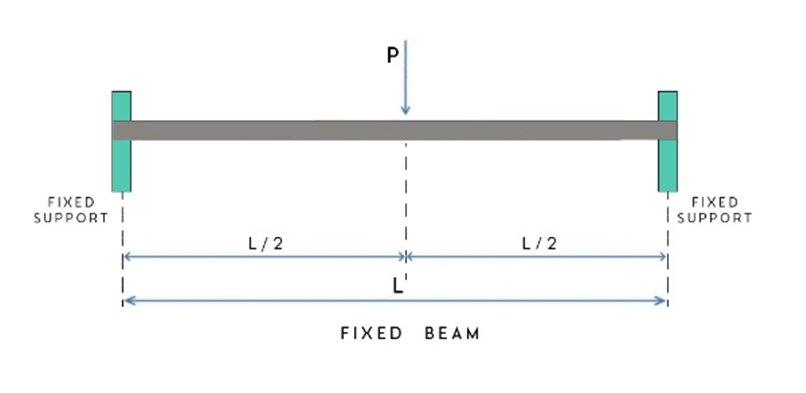

- Fixed Beam: As the name suggests these beams are confined with the supports at both ends and thus cannot rotate. The end supports are fixed that withstand on either column or wall. Fixed beams are used in high-rise buildings but the way of fixing them is different.

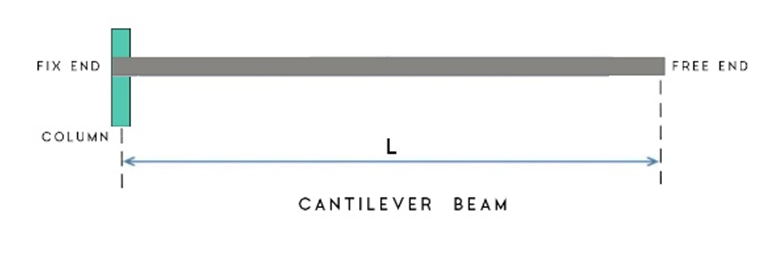

- Cantilever Beam: Cantilever beams are fixed at one end and set free at the other end. Load that is transferred on this beam is carried to the support where it is imposed against shear stress. For instance, cantilever beams are constructed in the balconies, bay windows, bridges, etc.

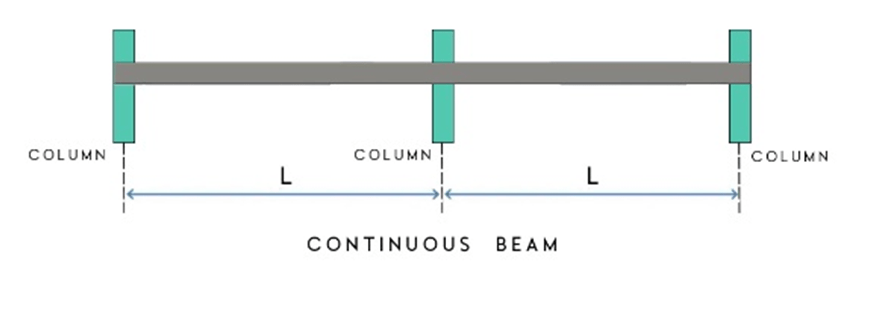

- Continuous Beam: Continuous beam is supported by more than two supports that are distributed along its length. It is simply supported beam where one end of the support is fixed while the rest follow thus creating multiple spans. These beams are mostly used in multi-story buildings with multiple bays working in perpendicular directions. As the maximum deflection capacity of a continuous beam is less than that of a simply supported beam these are preferred in the construction of bridges.

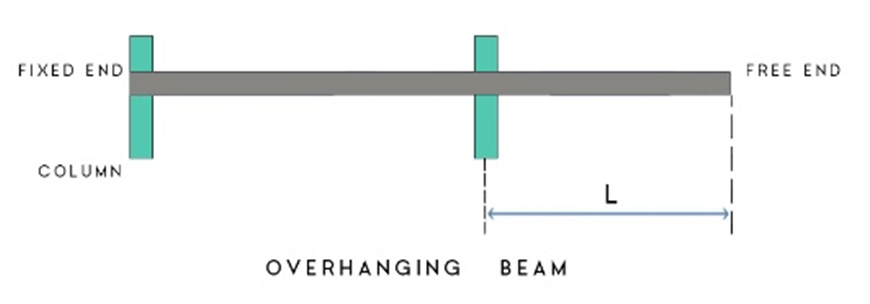

- Overhanging Beam: Overhanging beam has a fixed end at one side and the end portion on the other side extends beyond the support. This beam has a combination of attributes that of cantilever beam and simply supported beam. One end of this beam is supported by a column or wall and the other end is overhanging. These beams are used to construct shades or balconies that in residential buildings vary from 40-120cm.

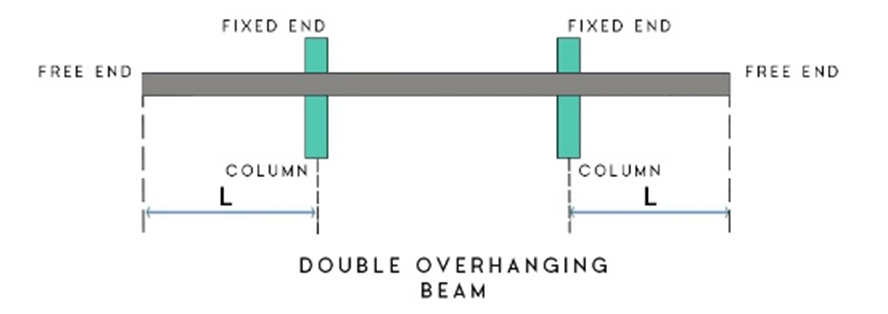

- Double overhanging beam: Double overhanging beam is similar to the overhanging beam with a difference of both the ends extending the supports and overhang. Both these ends have roller support and rotational moment.

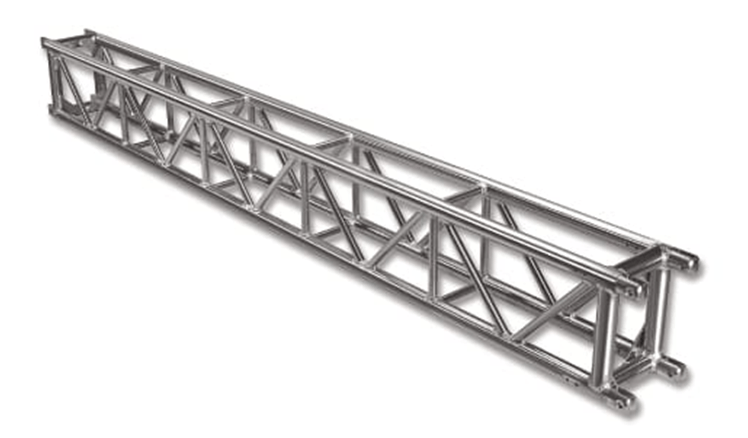

- Trussed Beam: Trussed beams are reinforced by truss rods or cambered segments connected. Workshop sheds, warehouse sheds are constructed using truss beams as these spaces need long spans and open space.

2. Based on Construction Material:

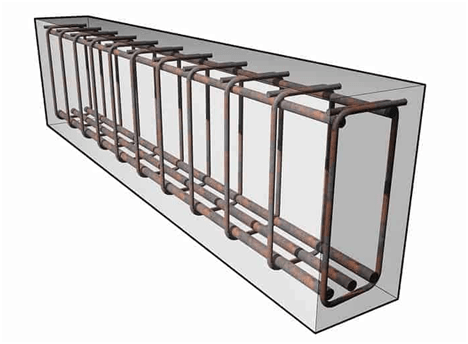

Reinforced Concrete Beam: Reinforced concrete beams are the horizontal structural members that carry transverse external loads. These are important members loaded to cause bending moment and shear force. In reinforced concrete beam concrete is strong in compression and the reinforced steel rods are used to carry the tensile stress. These beams transfer the load to the columns from their supporting slabs other beams, walls, and other columns. Sometimes these beams are designed as concealed beams inside slabs and these are called concealed or hidden beams.

- Steel Beams: Steel beams are available in a variety of shapes that are made using molds in which molten steel is poured. Compared to the other construction materials steel beams are durable, strong, and have high strength. Thus these columns are used in the construction of workshops, steel roof truss, warehouses, construction of bridges, etc.

- Timber Beams: Timber beams were used extensively in the past but the use of such beams in construction is refused nowadays after the introduction of concrete and other construction materials. As the name suggests these beams are made of timber and are used in the roof truss construction. The column posts that support the timber beam in the frame are also made of timber. Timber with proper treatment is durable and strong.

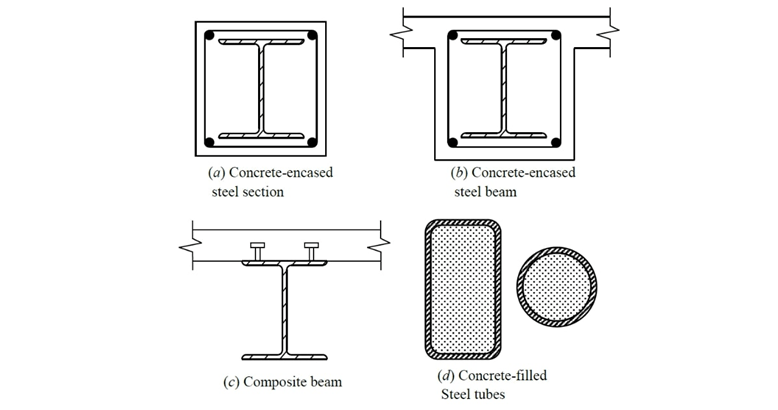

- Composite Beam: When a combination of two or more types of materials is used to construct a beam, that unit is called a composite beam. These beams are chiefly constructed in a truss structure to prevent the steel from corrosion. In the construction of these beams, the concrete slab is connected with a steel wide flange.

3. Based on Cross-Section Shapes:

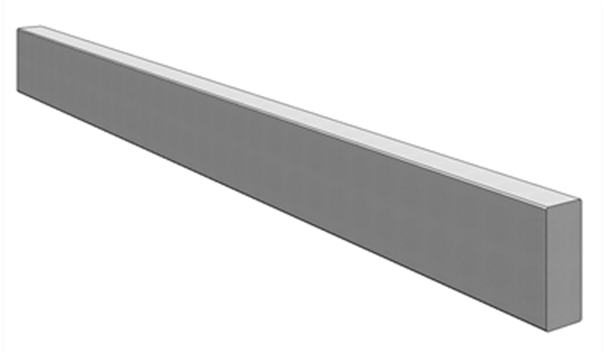

- Rectangular Beam: The beam that has a rectangular cross-section is a rectangular beam. Rectangular beams have more reinforcement at the bottom in comparison to the top half as it experiences compression at the top of the beam and tension at the bottom. These are the beams that are used normally in the construction of a reinforced concrete structure from a small house to high rise buildings.

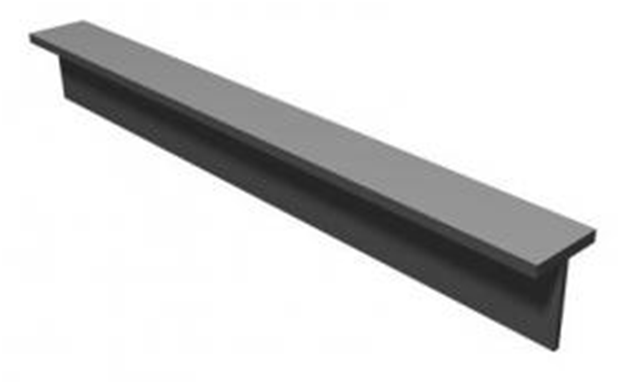

- T Section Beam: These beams have a T shaped cross-section and are constructed monolithically with a reinforced concrete slab and are better known as T section beam. T section beams that are constructed individually increase the compression strength. The slab as a result becomes a fundamental part of the slab and bends in the length direction of the beam. When T section beams are used the deflection of the slab is reduced and thus allows larger column-free spans. Depending on the loading requirement inverted T section beams are constructed.

- L Section Beam: Beams that have an L shaped cross-section and are constructed at the corner or along the perimeter of a slab are L section beams. These are alternatively known as end beams as they have slab only on one side. They work as L beams because they are cast monolithically with the slab and not as a rectangular beam. L beams are constructed in the roof slab that does not have any projections, staircase corners, lift openings, etc.

- I Section Beam: Cross-section of an I beam is shaped like the alphabet ‘I’. This structural member has a crossbar at the top and bottom with a central web. These beams are widely used in multi-story buildings and manufacturing plants and are available in a variety of materials like fiberglass, concrete, steel, etc.

- C Section Beam: C section beam has a C channel as the structural member of the beam. These are made in steel and used in reinforcement or as the sole horizontal member.

4. Based on Geometry:

- Straight Beam: Majority of beams constructed are straight beams as they have a straight form along the length and are supported at both ends. These beams carry the shear force and bending moment.

- Curved Beam: Curved Beam as the name suggests has a curved profile and is supported at two ends. These beams are constructed to support circular or curved shaped building. Curved beams carry bending moment, shear force, and torsional force.

- Tapered Beam: Tapered Beam has a straight profile as that of a straight beam but the cross-section of one end is smaller than the other end. A tapered beam works more like an I beam.

5. Based on Equilibrium Condition:

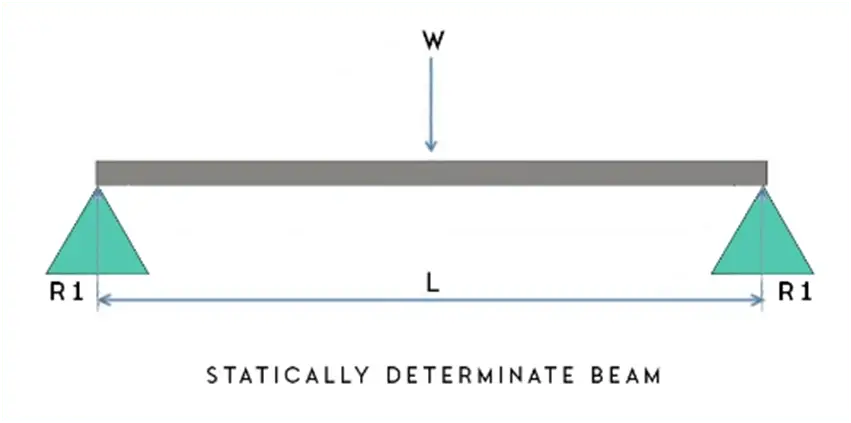

- Statically Determinate Beam: In a statically determinate beam the forces acting on the beam can be resolved only by applying static equilibrium equations. For instance, simply supported beams and overhanging beams are statically determinate beams. In these beams, the forces that are not determined are equal to the equations. These beams are widely constructed to support bridges as changes in the temperature can cause increased stress in the bridges.

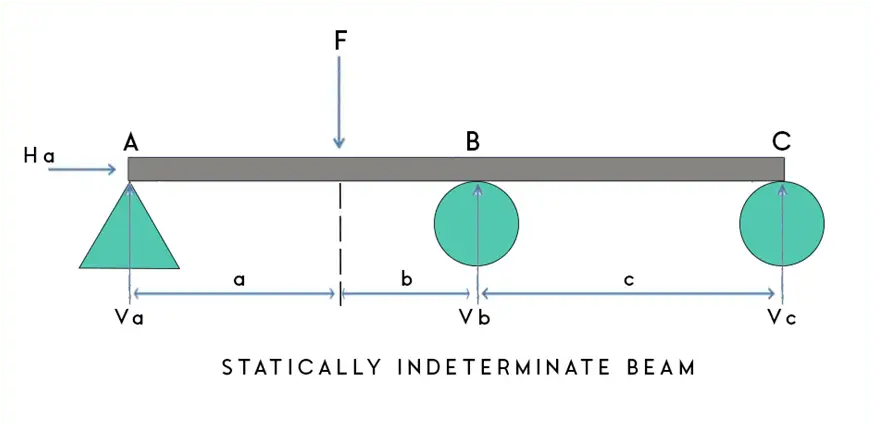

- Statically Indeterminate Beam: When the equilibrium conditions alone are not enough to resolve reactions those beams are termed as statically indeterminate beams. For instance, continuous beams, U beams, fixed beams are examples of statically indeterminate beams. These beams are comparatively complicated than the statically indeterminate beams. In these beams, the number of unknown forces is more than the number of equations. Also if compared to determinate structure indeterminate beams produce lower stress. As the stiffness is more the deflection of the beam is less. Indeterminate beams redistribute the loads that means that if there is a member failure, the entire structure will not definitely collapse as the load will be redistributed to the adjoining member of the structure.

6. Based on Method of Construction:

- Cast In-Situ Concrete Beam: Beams that are cast on-site and cured are known as cast an in-situ concrete beam. Depending on the design of the beam the form-work is fixed in the required size and for casting fresh concrete is poured and cured in this mould. For compaction that includes removing the air bubbles, various vibratory equipment is used. For instance, slab, beam formwork, etc. are some moulds that are cast on-site, and then the force is imposed.

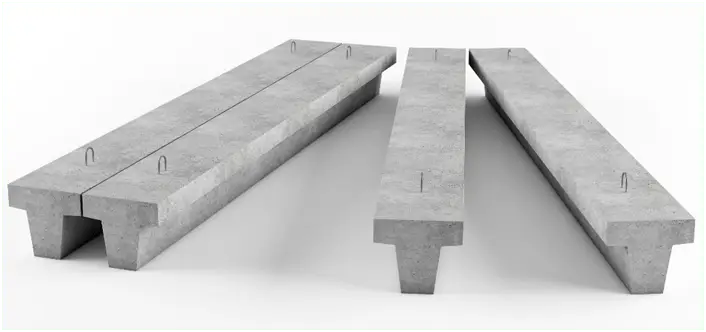

- Pre-Cast Concrete Beam: Contrasting to the method of cast-in-situ, precast concrete beams are manufactured in a plant and thus are more controllable in terms of construction. These plants are away from the structure that has a very controlled environment, and this is the ideal condition to ensure maximum strength of a beam. After a high-quality check, the precast beams are transported to the site. For instance, these beams are available in various cross-sectional shapes like a T beam, Inverted T-beam, T- beam, etc.

- Pre-Stressed Concrete Beam: As the name suggests pre-stressed beams are bestowed with pre-compression on the concrete and by stressing stands i.e. tensioned steel wires or cables before casting. Pre-loading the beams prevents them from minor cracks after positioning them in place. The wire is stressed with the help of a hydraulic jack before concreting. As the concrete is strong in compression the beams are pre-stressed thus keeping them under compression than in tension. These are further bifurcated in pre-tensioned and post-tensioned concrete beams.

7. Other Types of Beam:

- Deep Beam: As the name advocates these beams are deep, i.e. have a significant depth and the span to depth ratio is less than four. The advantage is that deep beams carry a considerable load to the supports by compression force. In conventional beams the strain force is linear, but in a deep beam, it is not the same case.

- Girder Beam: Girder beam is a type of support beam that is capable of carrying heavy loads. These have I-shaped cross-sections mostly made of steel designed with two load-bearing flanges and a web to balance.

- Lintel Beam: Lintel beams are one of the essential components that are constructed for openings like doors and windows. These beams are constructed to restrict the load to be transferred to the door and window frame. Lintel beam transfers the load from the upper structure to the sidewalls that support the beam.

References:

- https://theconstructor.org/structural-engg/types-beams-construction/24684/

- https://www.civilgyan.com/different-types-of-beam-and-its-classification/

- https://civilplanets.com/types-of-beams/

- https://civiconcepts.com/2020/06/25-types-of-beam-their-use-in-construction/